27 February 2019: Sapphires heated with high temperatures and low pressures (~1kbar) first entered the market in 2009, becoming more common since 2016. This article examines the process in detail and looks at the question of whether a separate disclosure is needed for the treatment.

The following organizations have contributed to and endorse the contents of this article: CGL Central Gem Lab, Japan; CISGEM, Italy; German Gem Lab (DSEF), Germany; Dunaigre Consulting, Switzerland; Gemological Institute of America (GIA), USA; Gem and Jewelry Institute of Thailand (GIT); GJEPC-GTL, India; Gübelin Gem Lab, Switzerland; Hanmi Lab, South Korea; ICA|GemLab, Thailand; Lotus Gemology, Thailand; Swiss Gemmological Institute (SSEF), Switzerland.

For further information see:

- 4 Feb. 2019: Presentation on "Sapphire Heated with Pressure" at Gemstone Industry & Laboratory Conference (GILC) in Tucson) (GIT.or.th)

- 26 Feb. 2019: Squeezing Sapphire: Corundum treated with high temperatures and low pressure (HT+P) (GJEPC-GTL)

- Feb. 2019: Presentation on Sapphires Heated with Pressure (LMHC-Gemmology.org)

- Feb. 2019: Presentation on Sapphire Heated with Pressure (SSEF.ch)

- March 2019: Korean Language Article on Sapphire Heated with Pressure (Hanmi Lab)

- March 2019: Japanese Language Article on Sapphire Heated with Pressure (GCL Central Gem Lab)

- May 2019: Sapphires Heated with Pressure – A Research Update (InColor Magazine)

Discussion

Sapphires heated with high temperatures and low pressures (~1kbar; hereafter referred to as HT+P sapphire) first entered the market in 2009, becoming more common since 2016. In late 2018, GemResearchSwisslab (GRS) issued a study claiming that such stones had durability issues (Peretti et al., 2018, 2019). This was quickly followed up by a press release from the American Gem Trade Association (AGTA, 2018) stating that they would require separate disclosure of any sapphires treated with heat and pressure, under the category of HP. The AGTA also noted that, like all treatments, any documents going to the consumer would require not just codes, but "clear language" disclosure (e.g. sapphire treated with heat and pressure).

While the AGTA's stated reason for a different disclosure was because the treatment changed the quality of the stones, they sidestepped the issue that the treatment was already being "disclosed," just not with a different category. We believe one must ask if the changes produced by the HT+P treatment are something beyond what one could do with traditional heating? This article is an attempt to address the central question of whether or not the addition of modest pressure to the heat treatment process deserves separate disclosure to traders and consumers.

Timeline: A history of heat

In order to provide perspective on the pressure heating of sapphires in respect to other processes, we believe it is useful to review the history of corundum heat treatment.

circa 1045 AD: Low temperatures to remove blue tints from ruby/pink sapphire

The great polymath, al Beruni (b. 973; d. 1050 AD) describes the process of heating ruby in a furnace designed to melt 50 mithqals (212 grams) of gold. Since gold melts at 1064°C, we know the furnace was capable of reaching temperatures of 1100°C or greater, in air. We also know that this process is effective, as it is essentially what treaters do today to these types of ruby and pink/purple sapphire. (Beruni, 1989; Hughes et al., 2017). See also Early Heat Treatment.

Treaters practicing the ancient art of blowpipe heating in Ratnapura, Sri Lanka. As described by al Beruni ca. 1045 AD, the temperatures reached by this technique exceeds that of the melting point of gold (1064°C). From Hughes et al., 2014. Photo: Wimon Manorotkul, 2012. Click on the photo for a larger image.

Treaters practicing the ancient art of blowpipe heating in Ratnapura, Sri Lanka. As described by al Beruni ca. 1045 AD, the temperatures reached by this technique exceeds that of the melting point of gold (1064°C). From Hughes et al., 2014. Photo: Wimon Manorotkul, 2012. Click on the photo for a larger image.

1916: Low temperature (800–1200°C) heating to lighten blues

Heat treatment at low temperatures of dark blue (basaltic) sapphires from Queensland (Australia) to lighten their color. This process is later adapted for heating all dark blue sapphires and continues to this day. It is difficult to detect, as these stones have already experienced natural heating within the basaltic magma during their journey to the Earth's surface (Anonymous, 1916).

Basalt-related Madagascar sapphires before (left) and after (right) heating to 950°C for ten hours in air. This process, which has been used since at least 1916, is commonly used today to lighten dark blue sapphires. It is difficult to detect, as basalt-related sapphires are naturally heated by the magma that brings them to the earth's surface. Photos, specimens and heating: John Emmett. From Hughes et al., 2017. Click on the photos for larger images.

1966: Higher temperatures

The GIA's Robert Crowningshield reports on a sapphire that was reportedly from Thailand and yet displayed a weak iron spectrum and showed an unusual chalky short-wave ultraviolet fluorescence. We now know this fluorescence is commonly associated with high-temperature heating of geuda-type metamorphic sapphire (Crowningshield, 1966). Knowing what we know now, this appears to have been an early attempt at high-temperature heating of a low-iron metamorphic sapphire.

circa 1975: Enter the geuda

Diesel furnaces (1500°C+) are used to convert Sri Lankan geuda sapphires to blue. Addition of oxygen produces the higher temperatures needed to dissolve rutile. The process in most cases involves hydrogen diffusion in a reducing atmosphere. By the late 1970's the material flooded the market, with many buyers having no idea that they had been buying heated stones. Thus, in the 1980’s the trade blessed it as “traditional” heat treatment, even though the “tradition” then dated less than 20 years and was radically different from what had come before. New York's American Gemological Laboratories (AGL) was the first lab to begin disclosing this treatment; it was not until the late 1980's that other labs followed.

- Is it a modification of an earlier process? Yes.

- Does it insert chromophores from outside? No.

- Does it recrystallize/heal significant fissures of the stone? Sometimes.

- Is separate disclosure (beyond 'heat') now required? No.

1980: Titanium lattice diffusion

Entry of titanium lattice-diffused (then known as 'surface diffused') sapphires into the market. Although they are initially sold without proper disclosure by a major Swiss company that had bought the patent rights for the process from Union Carbide Corp., they are quickly identified and achieve little market penetration (Nassau, 1981).

- Was it a new treatment? Yes.

- Does it insert chromophores from outside? Yes.

- Is separate disclosure (beyond 'heat') now required? Yes.

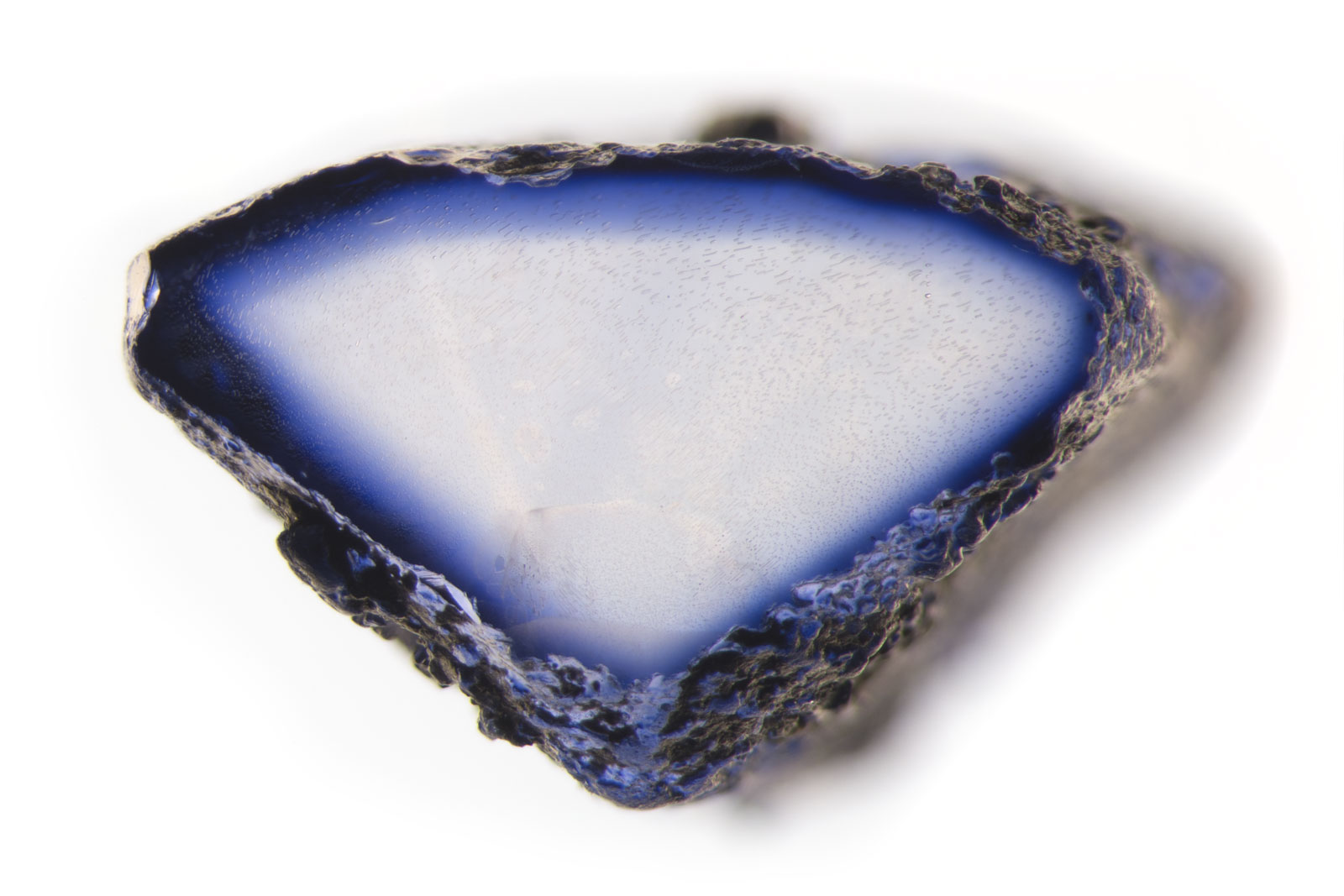

Near colorless sapphire that was lattice-diffused with titanium (Ti). It has been sliced through to show the depth of penetration of the Ti chromophore. Because the chromophore is added from outside the stone and because recutting the stone could produce a loss of color, this treatment requires special disclosure. From Hughes et al., 2017. Photo: E. Billie Hughes; specimen: AIGS. Click on the photo for a larger image.

Near colorless sapphire that was lattice-diffused with titanium (Ti). It has been sliced through to show the depth of penetration of the Ti chromophore. Because the chromophore is added from outside the stone and because recutting the stone could produce a loss of color, this treatment requires special disclosure. From Hughes et al., 2017. Photo: E. Billie Hughes; specimen: AIGS. Click on the photo for a larger image.

Early 1980's: Electric furnaces

Electric muffle furnaces are introduced, allowing better control over atmosphere and temperature; oxidizing atmospheres convert many Sri Lankan sapphires from pale blue to vivid yellow and orange and this material floods the market (Keller, 1982).

- Is it a modification of an earlier process? Yes.

- Does it insert chromophores from outside? No.

- Is separate disclosure (beyond 'heat') now required? No.

Mid 1980's: Flux healing

Additions of flux during heating produce fissure healing, where cracked stones are healed shut with submicroscopic amounts of synthetic corundum. When ruby is discovered at Mong Hsu in 1991, this material floods the market (Hughes et al., 1998; Hughes et al., 2004).

- Is it a modification of an earlier process? Yes.

- Does it insert chromophores from outside? No.

- Does it recrystallize/heal significant fissures of the stone? Yes.

- Is separate disclosure (beyond 'heat') now required? Yes.

Flux-healed fingerprint in a fissure-healed ruby from Mong Hsu, Myanmar. The flux acts as a solvent, dissolving the fissure walls of the ruby and redepositing the now synthetic corundum in the fissure, healing it closed. Because this treatment involves recrystallization of the ruby, it requires a separate disclosure. Note that the same process can occur in heat treated corundums without the addition of a flux and this is often not disclosed. From Hughes et al., 2017. Photo: Wimon Manorotkul. Click on the photo for a larger image. For more on this treatment see "Fluxed up: The fracture healing of ruby."

Flux-healed fingerprint in a fissure-healed ruby from Mong Hsu, Myanmar. The flux acts as a solvent, dissolving the fissure walls of the ruby and redepositing the now synthetic corundum in the fissure, healing it closed. Because this treatment involves recrystallization of the ruby, it requires a separate disclosure. Note that the same process can occur in heat treated corundums without the addition of a flux and this is often not disclosed. From Hughes et al., 2017. Photo: Wimon Manorotkul. Click on the photo for a larger image. For more on this treatment see "Fluxed up: The fracture healing of ruby."

Mid 1990's–2001: Beryllium diffusion

Beryllium diffused corundums slowly infiltrate the market. The process is later sold, resulting in a flood of material by the year 2001. Gemologists identify the cause in early 2002 (Emmett et al., 2003).

- Is it a modification of an earlier process? Yes.

- Does it insert chromophores from outside? Yes.

- Does it recrystallize/heal significant fissures of the stone? Yes.

- Is separate disclosure (beyond 'heat') now required? Yes.

Top: Sri Lankan geuda sapphire before (left) and after (right) high-temperature (1500°C+) heating. Below: Madagascar sapphire before (left) and after (right) high-temperature (1700°C+) heating with beryllium (Be). Geuda heat treatment requires only that it be disclosed as heat (H), while Be diffusion requires special disclosure because a chromophore (Be) is inserted into the stone from outside and also because the recutting of some stones may result in loss of color. From Hughes et al., 2014. Photos: Wimon Manorotkul; specimens and heating: John Emmett. Click on the photo for a larger image.

Top: Sri Lankan geuda sapphire before (left) and after (right) high-temperature (1500°C+) heating. Below: Madagascar sapphire before (left) and after (right) high-temperature (1700°C+) heating with beryllium (Be). Geuda heat treatment requires only that it be disclosed as heat (H), while Be diffusion requires special disclosure because a chromophore (Be) is inserted into the stone from outside and also because the recutting of some stones may result in loss of color. From Hughes et al., 2014. Photos: Wimon Manorotkul; specimens and heating: John Emmett. Click on the photo for a larger image.

2000–2003: Longer heating times, more sophisticated regimens

Longer heating times allow treaters to better dial in the finished color. Treaters undertake extensive experiments to improve their processes, culminating in the "Punsiri" crisis, where a Sri Lankan treater's stones were initially suspected of being a potential problem, but were later shown to be just a sophisticated variation on standard heat treatment.

- Is it a modification of an earlier process? Yes.

- Does it insert chromophores from outside? No.

- Does it recrystallize/heal significant fissures of the stone? Sometimes.

- Is separate disclosure (beyond 'heat') now required? No.

Shortly after the discovery of beryllium diffusion, gemologists found unusual zoning patterns in heated sapphire. These were traced back to the oven of Punsiri Tennakoon of Sri Lanka. After much study, it was determined that the features were the result of a sophisticated variation in heating, and no special disclosure (beyond heating) was required. Photo: Richard W. Hughes; specimen: Pala International. Click on the photo for a larger image.

Shortly after the discovery of beryllium diffusion, gemologists found unusual zoning patterns in heated sapphire. These were traced back to the oven of Punsiri Tennakoon of Sri Lanka. After much study, it was determined that the features were the result of a sophisticated variation in heating, and no special disclosure (beyond heating) was required. Photo: Richard W. Hughes; specimen: Pala International. Click on the photo for a larger image.

2003: Beryllium diffusion to lighten dark blue sapphire

Diffusion of beryllium into blue sapphire to lighten the color. This material slowly infiltrates the market as it requires sophisticated equipment to identify (Emmett et al., 2003).

- Is it a modification of an earlier process? Yes.

- Does it insert chromophores from outside? Yes.

- Does it recrystallize/heal significant fissures of the stone? Sometimes.

- Is separate disclosure (beyond 'heat') now required? Yes.

2009–present: Sapphires heated with pressure (HT+P)

Entry of blue sapphire treated by pressure plus high- temperature heat (Choi et al., 2014a, b). These stones started to appear slowly in the market.

- Is it a modification of an earlier process? Yes.

- Does it insert chromophores from outside? No.

- Does it recrystallize/heal significant fissures of the stone? Sometimes.

- Does it have durability problems? Not from what we can see.

- Is separate disclosure (beyond 'heat') now required? This is the burning question.

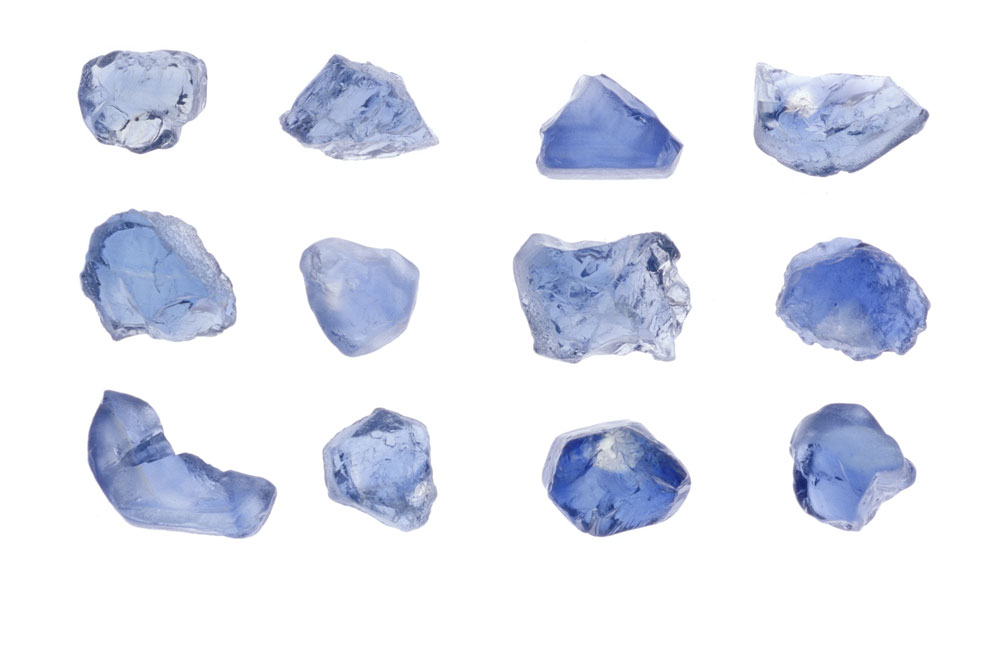

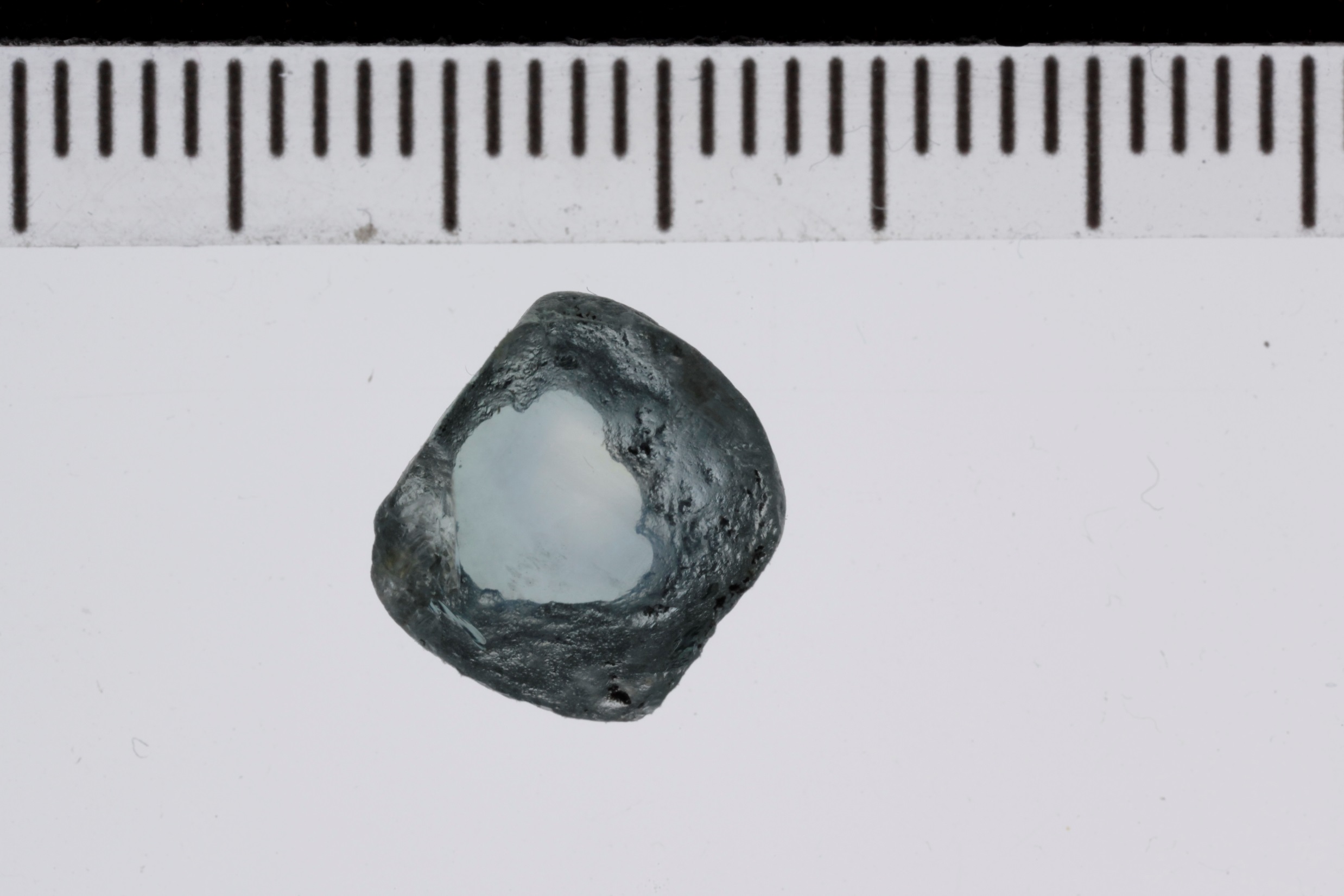

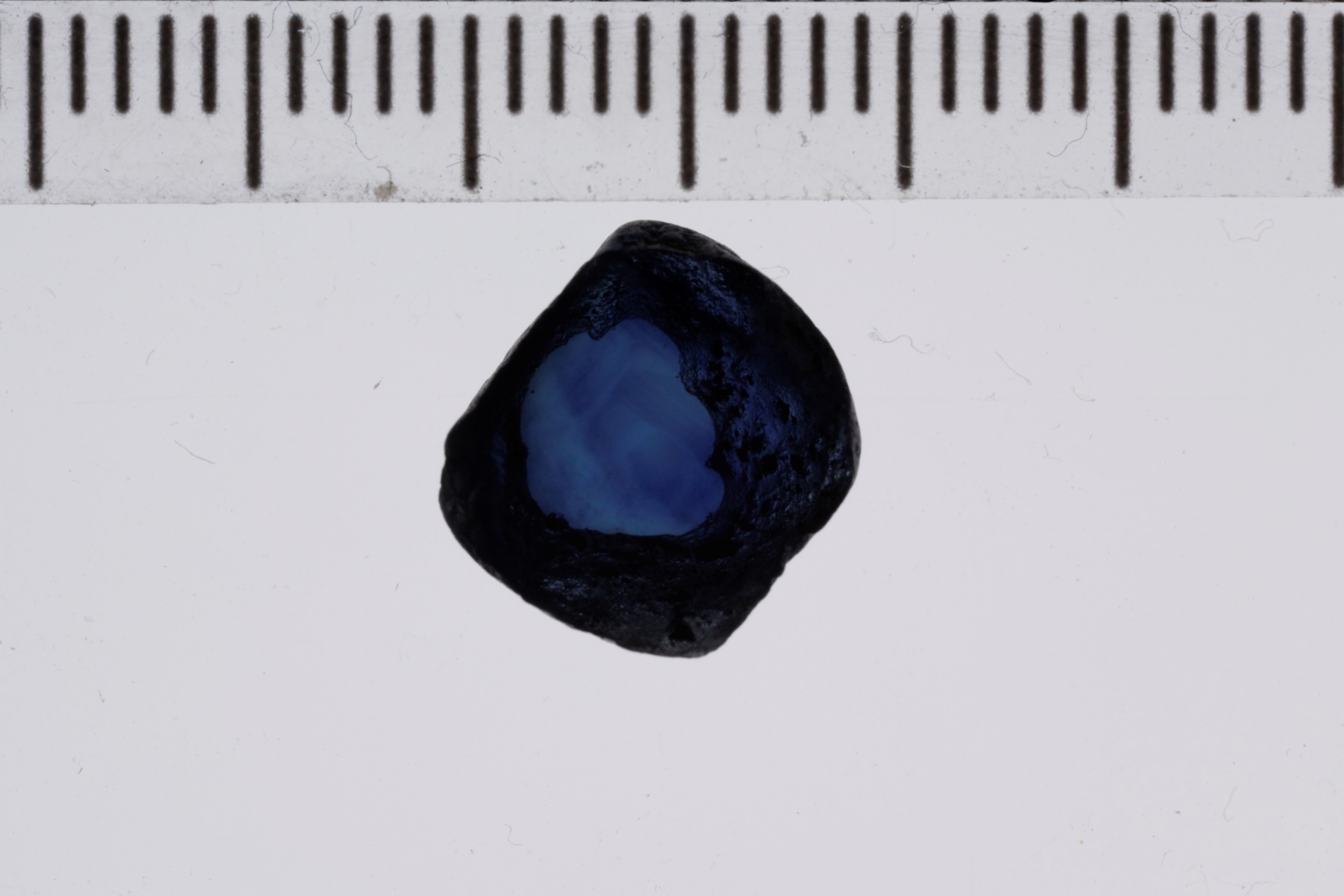

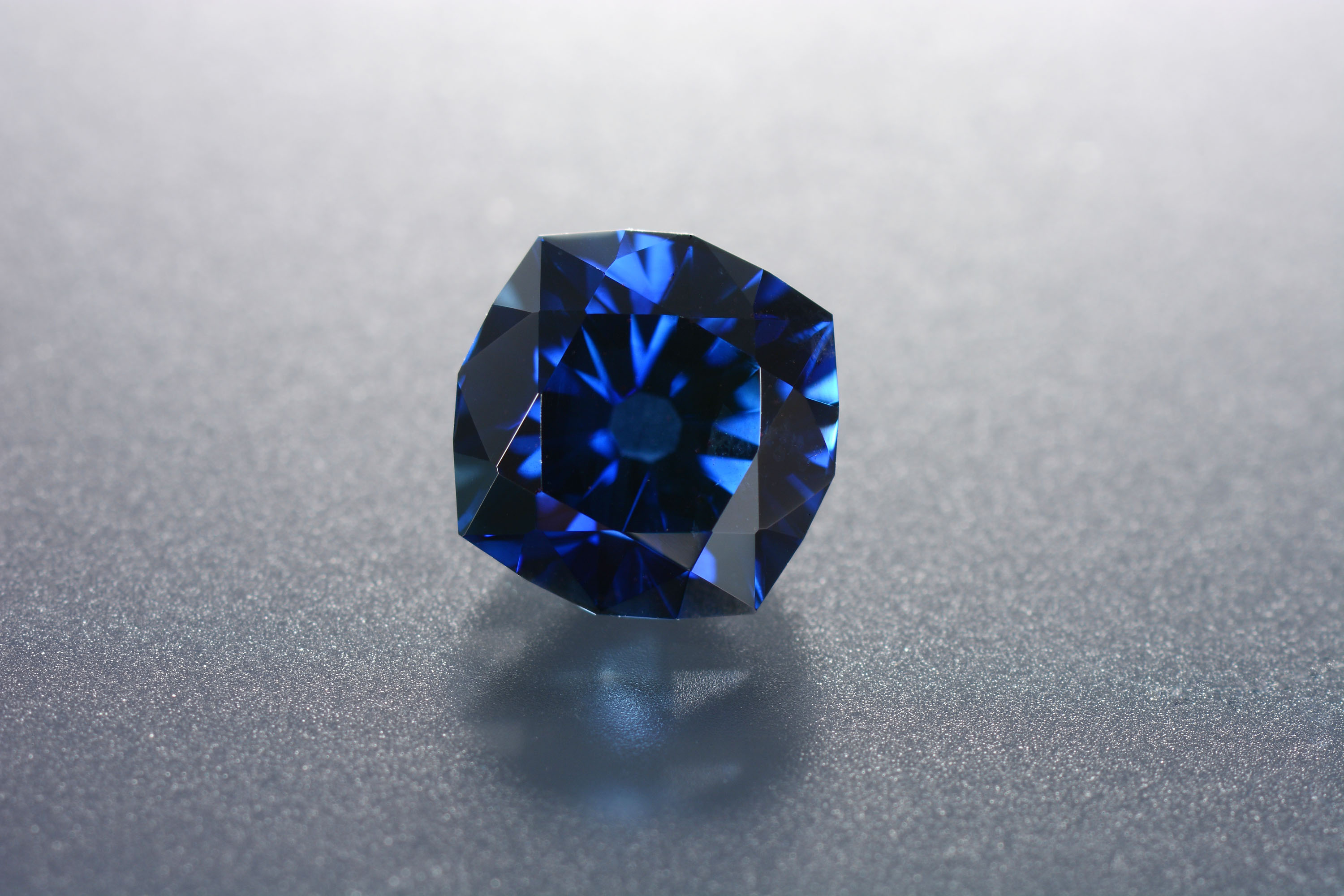

HT+P treated sapphires. Photo: SSEF. Click on the photo for a larger image.

HT+P treated sapphires. Photo: SSEF. Click on the photo for a larger image.

From the above it is clear that the gem trade's record on treatment disclosure has been uneven, at best, and was often based on the market penetration of the treated material prior to its identification by gemologists. When market penetration was high (high-temperature heating of geuda sapphires), the trade tended to "grandfather" it as "traditional"; where a treatment was caught early (beryllium diffusion), the trade was more critical. This is not unexpected or unusual. Humans look out for their own interests first.

That said, the current standards, according to the US Federal Trade Commission (FTC) guidelines and the AGTA disclosure policies, are as follows (AGTA, n.d.):

Treatment details must be disclosed when…

- The treatment is not permanent and its effects are lost over time; or

- The treatment creates special care requirements for the gemstone to retain the benefit of the treatment; or

- The treatment has a significant effect on the value of the gemstone.

In regard to the new high heat + low pressure (HT+P) treatment, are any of the above disclosure conditions met? These are important questions that this article will attempt to answer.

Under pressure

Diamond treaters have been using high temperatures and high pressures to improve color since the 1990's. Thus it was only a matter of time that corundum cookers would look at using pressure in the heat treatment of ruby & sapphire. Indeed, starting in 1997, the German Furnace company LINN offered autoclaves with low pressure for sale for corundum treatment (up to 25 bar). Several of these were sold to Asia. Similarly, those involved in heating tourmaline have long used pressure heating to produce changes in color without causing the explosion of fluid-filled negative crystals. The treatment (temperatures less than 700°C; pressure 0.5–1.5 kbar) continues to this day and is basically undetectable.

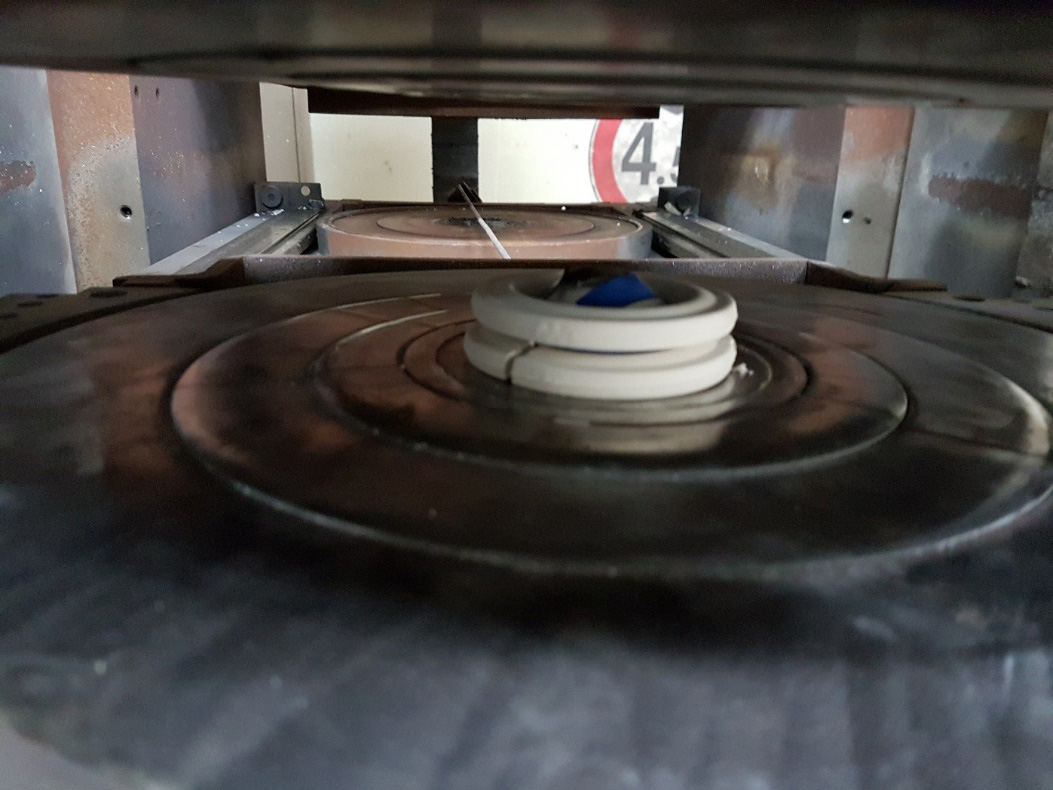

When it comes to the HT+P treatment of sapphire, the pressures used (~1kbar) are much lower. Compared with the pressures that sapphires grow under in the ground, the treatment pressures are nowhere near enough to prevent the rupture of fluid-filled negative crystals in the gem. Indeed, the sapphires that are used in this treatment are often stones that have been previously heated at high temperatures. This brings up the question: why is the HT+P treatment being used? The answer is that it is far quicker, allowing stones to be treated in 30 minutes or less.

But there are disadvantages, too. The heating apparatus is far more expensive than typical treatment ovens. And in most cases, only one stone can be treated at a time. In addition, the phase change that produces the change of color occurs so rapidly that it is more difficult to control. This is one reason why the treatment has produced such mixed results.

Squeezing sapphire: The HT+P treatment methodology

The following information is based largely on visits to the heating facility in South Korea by Hanmi Lab, GIT Thailand, and GIA.

Starting material used for HT+P treatment

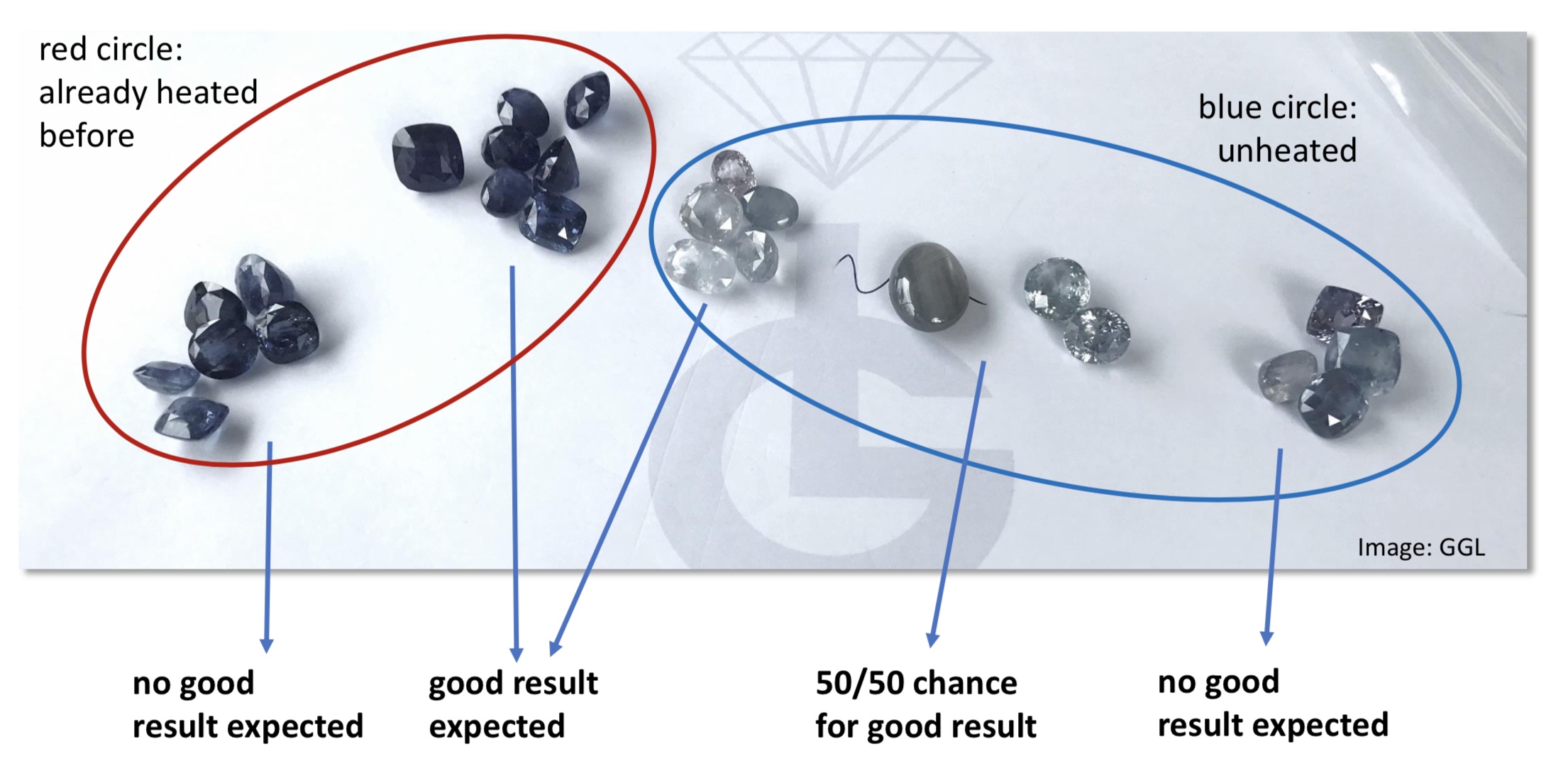

Parcel of sapphires for treatment at the factory. Photo: Shane McClure, GIA. Click on the photo for a larger image.

Parcel of sapphires for treatment at the factory. Photo: Shane McClure, GIA. Click on the photo for a larger image.

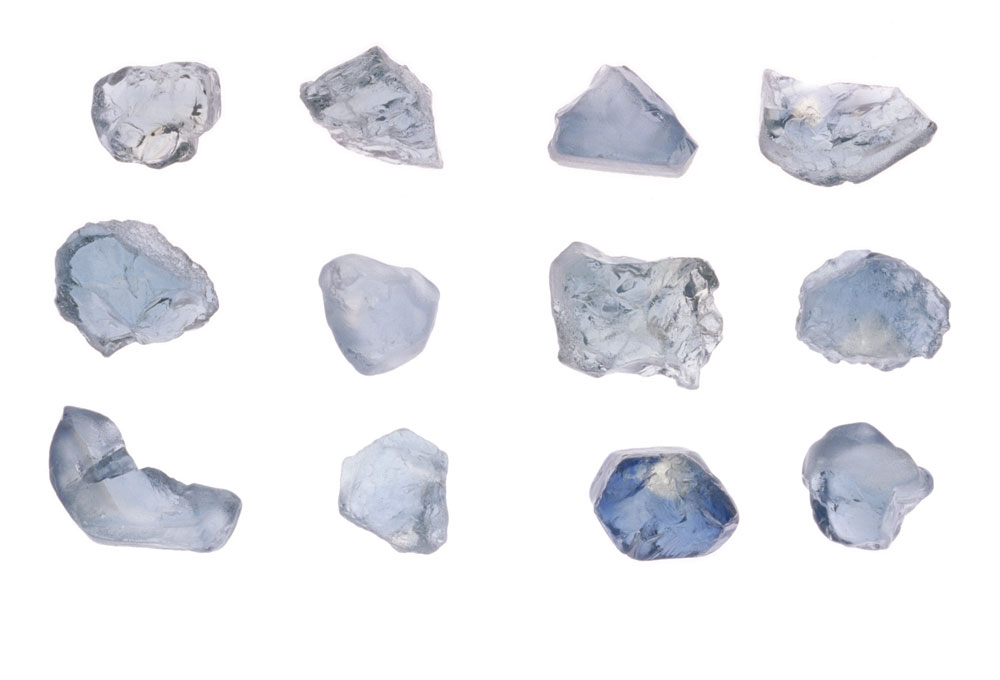

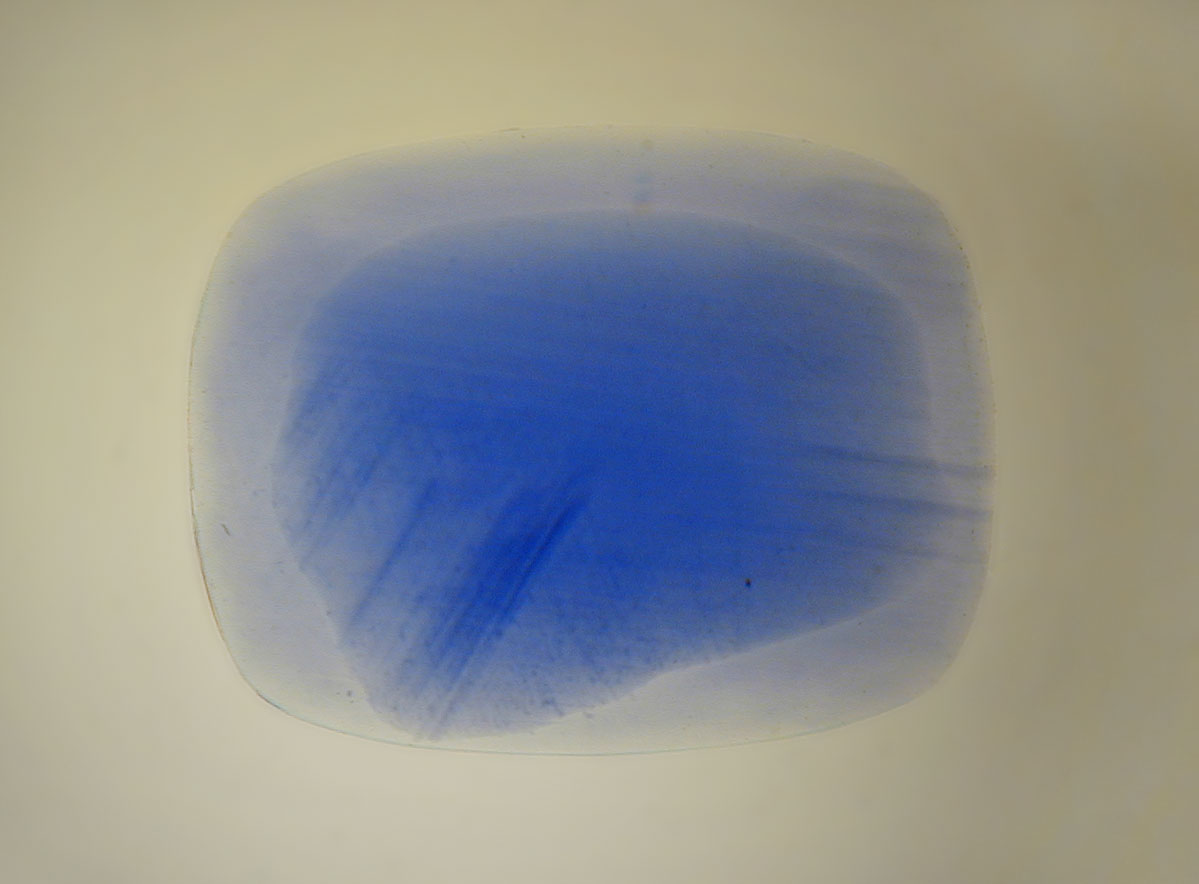

Starting material for the HT+P treatment. Note that much of the material being used for this treatment has already been conventionally heated. Photo: Lore Kiefert, GGL. Click on the photo for a larger image.

Starting material for the HT+P treatment. Note that much of the material being used for this treatment has already been conventionally heated. Photo: Lore Kiefert, GGL. Click on the photo for a larger image.

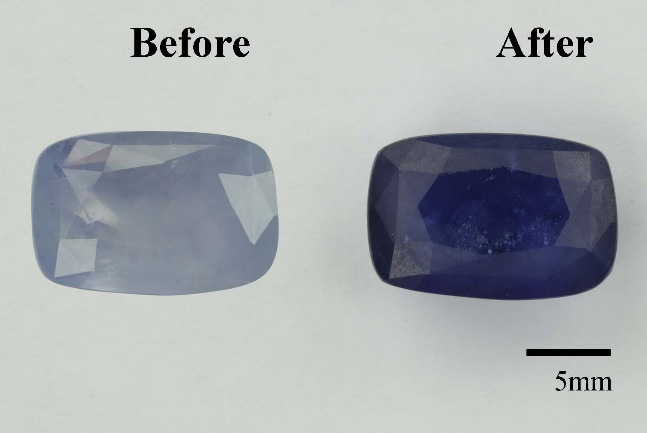

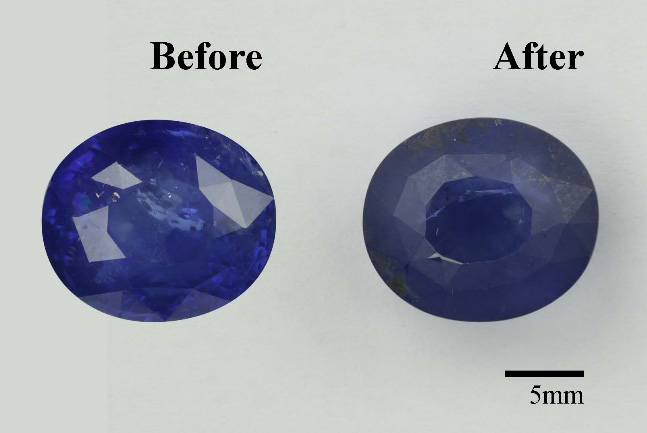

Three examples of sapphires before and after HT+P treatment. Photos: GIT.

Top: Conventionally heated sapphires prior to undergoing HT+P treatment.

Bottom: The same sapphires after HT+P treatment. As with conventional treatments, results vary according to the chemical makeup of the starting material. From Choi et al., 2018. Photos by P. Ounorn.

Identification of HT+P treated sapphire

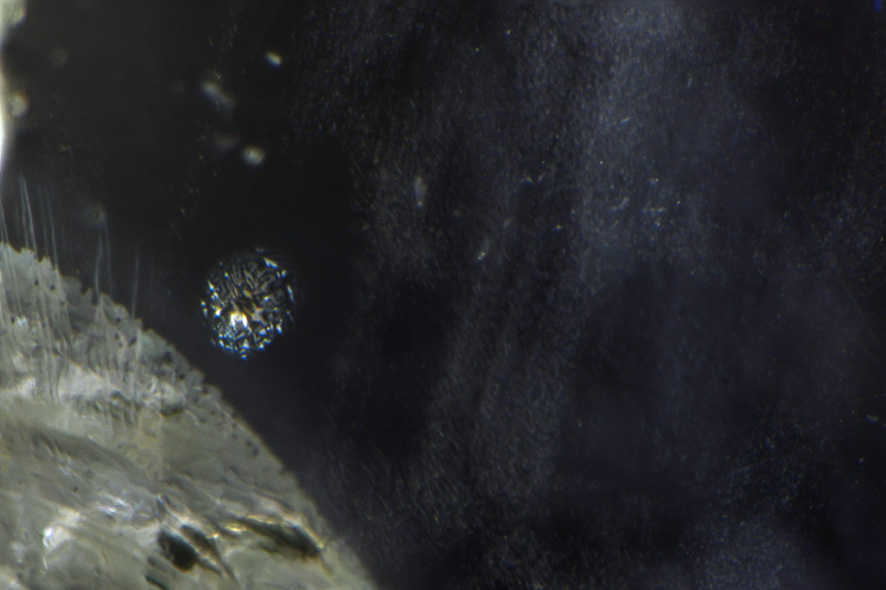

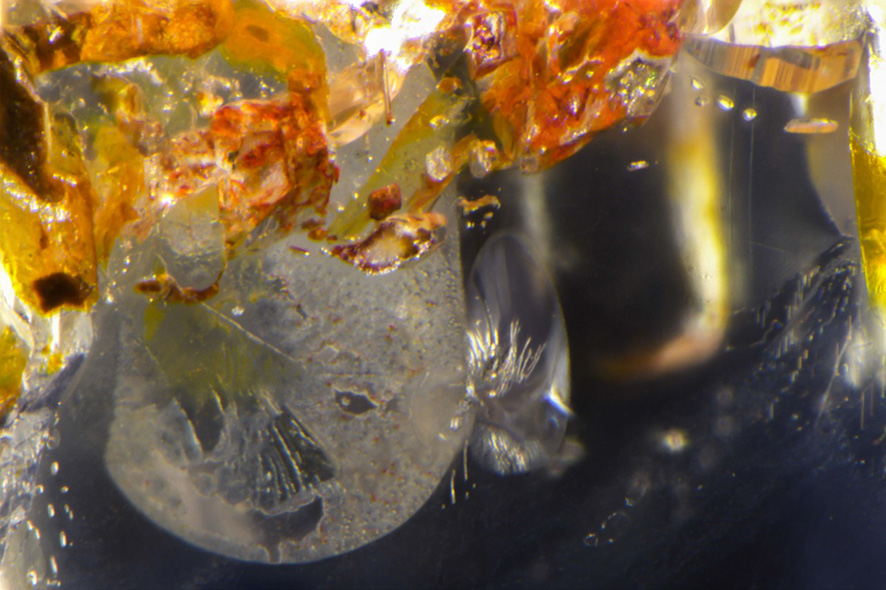

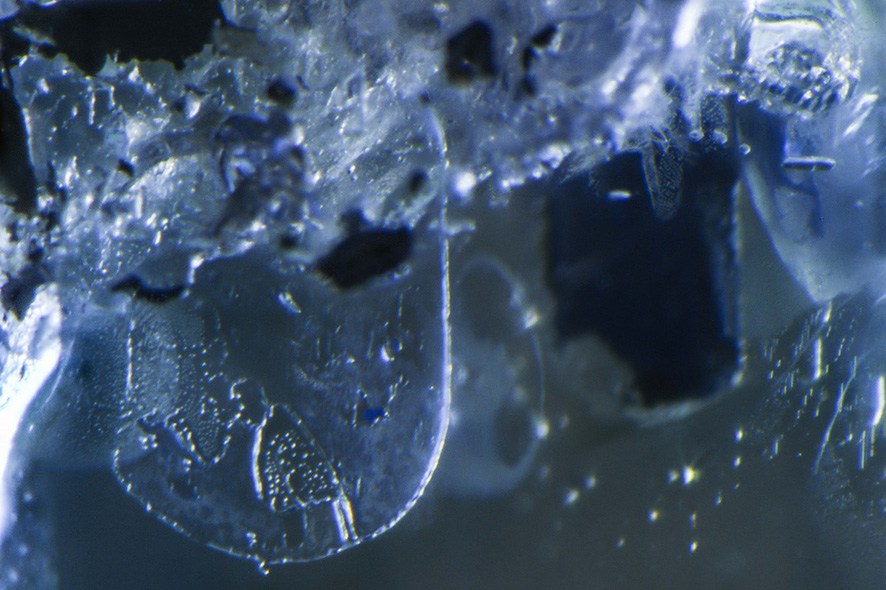

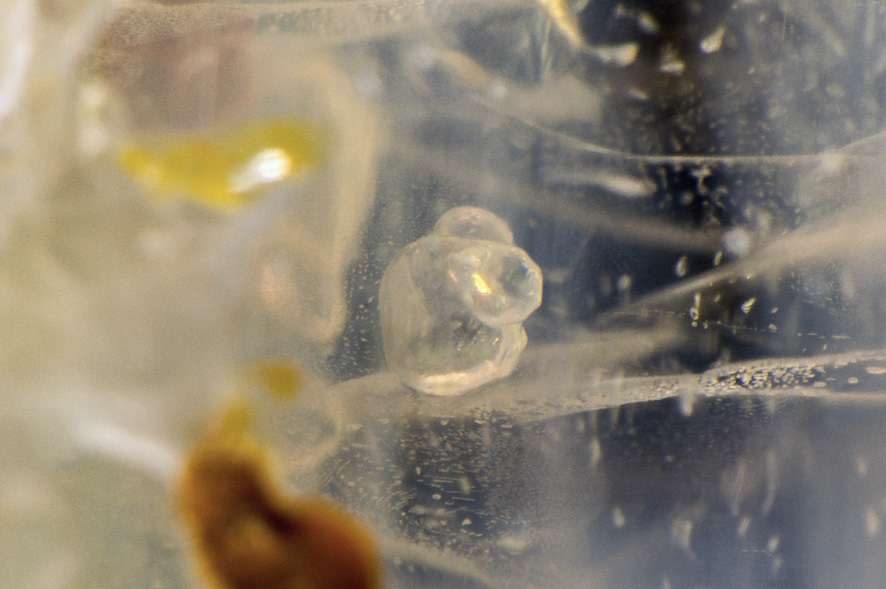

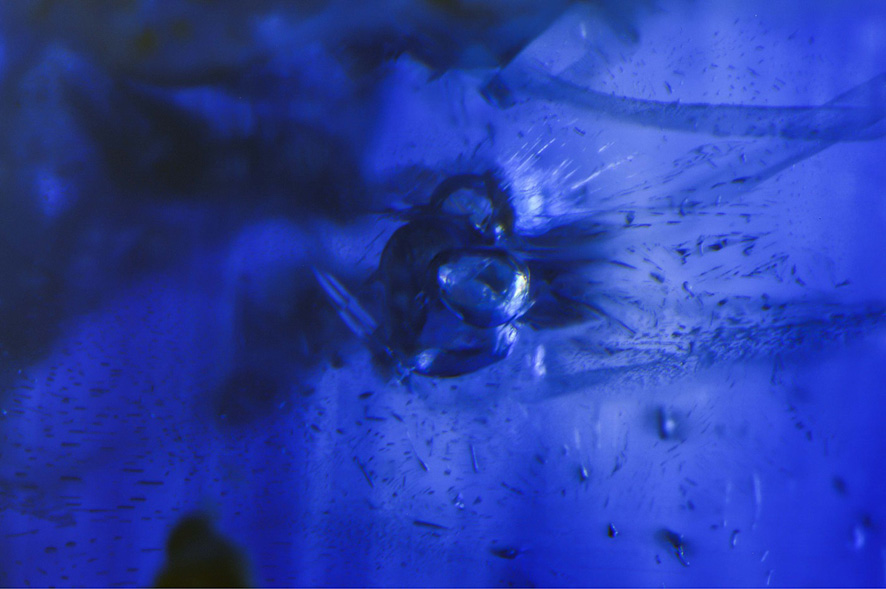

Inclusions

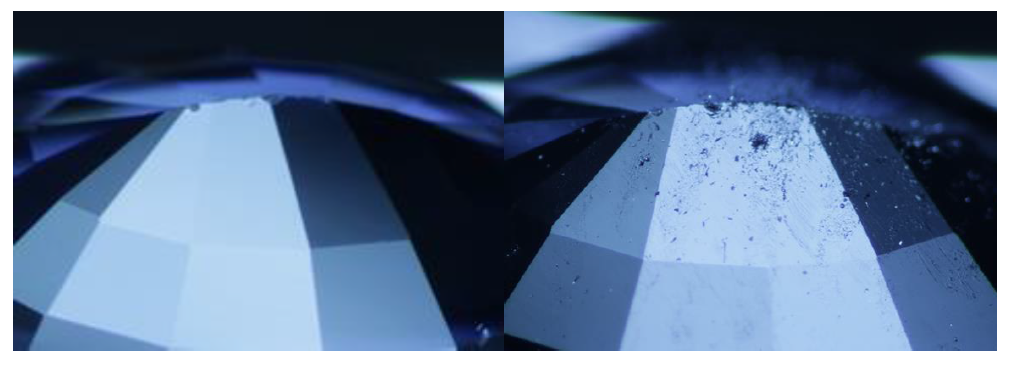

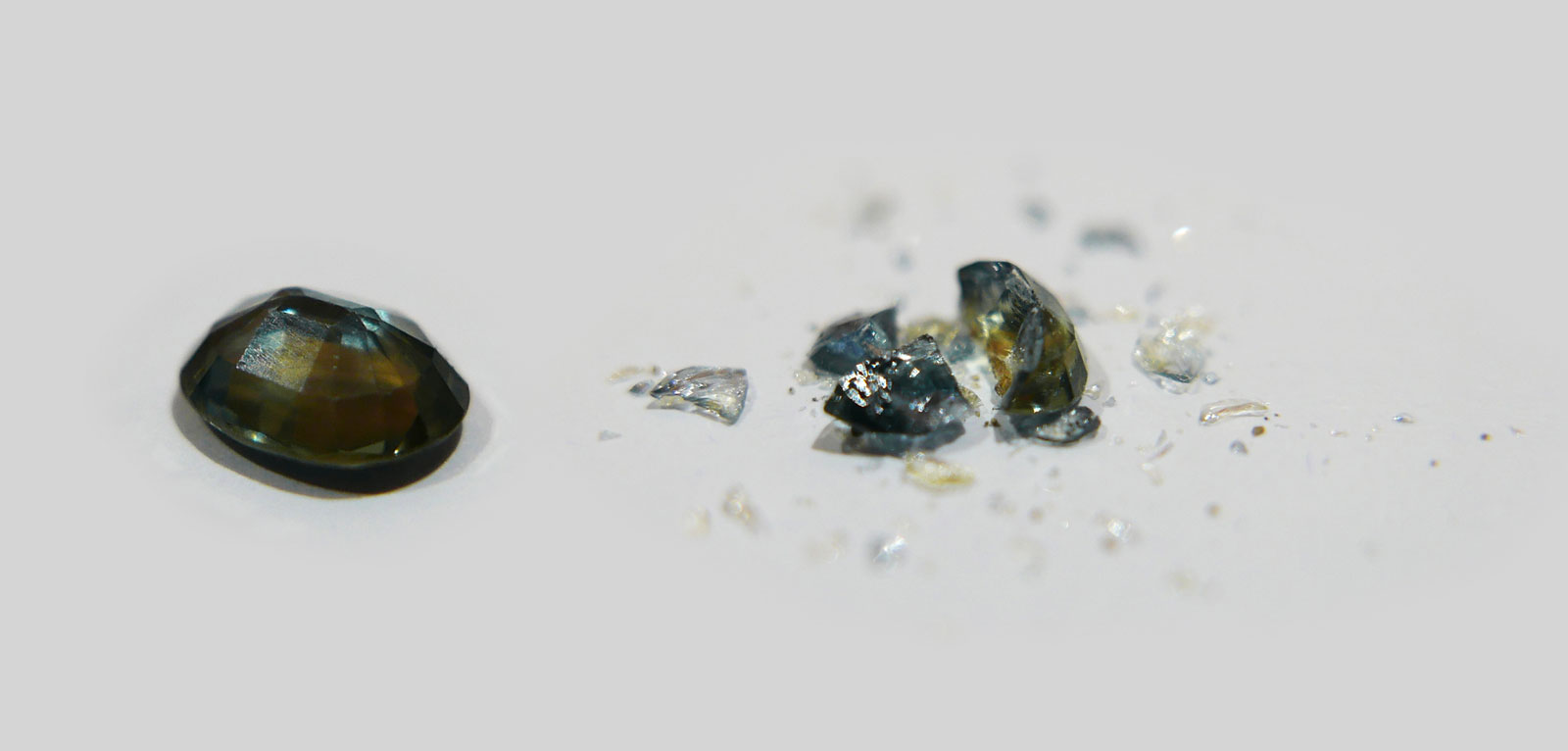

HT+P sapphire before (left) and after (right) treatment. In this case, the treatment caused serious damage to the stone. Photos: GIT. Click on each image for a larger view.

HT+P sapphire before (left) and after (right) treatment. In this case, the treatment produced a slight improvement in clarity due to the healing of a fissure. Photos: GIT. Click on each image for a larger view.

HT+P sapphire before (left) and after (right) treatment. In this case, there was improvement in clarity due to the healing of the narrow-gap fissure at lower left and the halo around the crystal inclusion.. Photos: GIA. Click on each image for a larger view.

HT+P sapphire before (left) and after (right) treatment. In this case, after heating with pressure the iron staining was gone, while the fissure in the middle partially healed, but was still quite visible. Photos: GIA. Click on each image for a larger view.

HT+P sapphire before (left) and after (right) treatment. In this case, there was typical damage from high temperature heat treatment, and also a great improvement of color of the gem. Photos: GIA. Click on each image for a larger view.

Summary of microscopic observations of HT+P sapphire

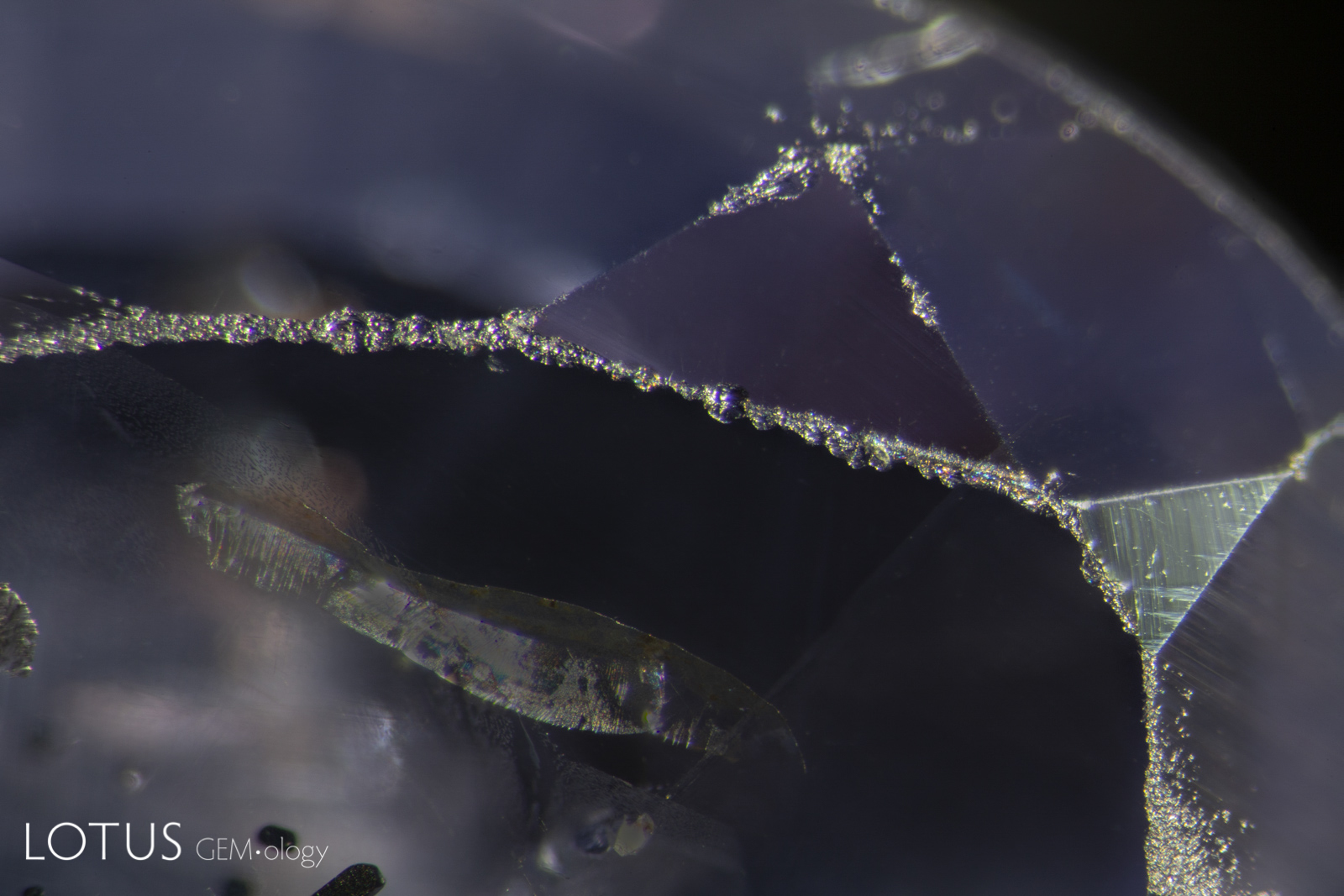

The features observed in HT+P sapphires were similar to those in “traditionally” high-temperature heated sapphires.

- Subtle differences were found in surface granularity of healed fissures. But similar features can also be seen in conventionally heated sapphires.

- Sometimes graphite accumulations were seen in fissures and cavities close to the surface (remnants of the graphite filled crucible).

In most cases, microscopic observations did not provide sufficient evidence to separate this treatment from ordinary heat treatments. From the above images, we can see that the types of changes resulting from the treatment were virtually identical with what one could expect from high temperature heat treatment without pressure.

Other tests

A number of other gemological tests were performed on HT+P-treated sapphires. These included…

Ultraviolet (UV) fluorescence

It is well known that many sapphires treated by traditional heat treatment will show a chalky fluorescence under shortwave (SW) ultraviolet light. This is particularly true of sapphires from metamorphic environments with relative low iron contents (such as Sri Lanka, Burma, Madagascar, and Kashmir). Since HT+P-treated sapphires are heated in a similar way and the starting material tends to be low iron metamorphic material, we would expect similar reactions and this is what we found. Long wave UV did not produce any diagnostic difference between natural or normally heated sapphires and those treated by the HT+P process. SW UV produced reactions similar to traditionally heated stones.

Long wave UV did not produce any diagnostic difference between natural or normally heated sapphires and those treated by the HT+P process. SW UV produced reactions similar to traditionally heated stones. The above photo shows the SW fluorescence of 12 HT+P treated sapphires. This can be useful for separation from untreated sapphire, but does not allow the separation from sapphires treated by traditional heating. Photo: Klaus Schollenbruch, GGL. Click on the photo for a larger image.

Long wave UV did not produce any diagnostic difference between natural or normally heated sapphires and those treated by the HT+P process. SW UV produced reactions similar to traditionally heated stones. The above photo shows the SW fluorescence of 12 HT+P treated sapphires. This can be useful for separation from untreated sapphire, but does not allow the separation from sapphires treated by traditional heating. Photo: Klaus Schollenbruch, GGL. Click on the photo for a larger image.

Trace element analysis

LA-ICP-MS tests on 12 samples from GGL gave the following results (average of three laser spots per sample; in ppmw; NIST glasses and internal standards used for calibration). Specifically, there was no evidence of diffusion of lithium, beryllium or titanium.

| Sample | Li | Be | Mg | Ti | V | Cr | Fe | Ga |

| SAXX064 | <0.09 | 1.0 | 80 | 110 | 7 | 4.5 | 530 | 120 |

| SAXX065 | 0.25 | 0.8 | 100 | 200 | 11.5 | 2.7 | 1700 | 165 |

| SAXX066 | 0.18 | 0.34 | 115 | 290 | 55 | 8 | 550 | 95 |

| SAXX067 | <0.1 | <0.22 | <0.6 | 34 | 1.4 | 2.0 | 2200 | 260 |

| SAXX068 | <0.1 | 0.19 | 120 | 220 | 7.5 | 22 | 480 | 61 |

| SAXX069 | <0.09 | <0.18 | 45 | 120 | 8 | 3.8 | 350 | 69 |

| SAXX070 | <0.08 | <0.16 | 50 | 150 | 8.1 | 6.5 | 380 | 75 |

| SAXX071 | <0.09 | <0.2 | 62 | 95 | 9.5 | 6.8 | 550 | 83 |

| SAXX072 | <0.09 | <0.17 | 77.5 | 120 | 12.7 | 6.0 | 590 | 60 |

| SAXX073 | <0.09 | 0.23 | 240 | 330 | 25 | 2.3 | 150 | 87 |

| SAXX074 | <0.15 | <0.5 | 240 | 700 | 18 | 8 | 1150 | 135 |

| SAXX075 | <0.09 | 0.25 | 160 | 270 | 28.2 | 3 | 480 | 66 |

UV-Vis-NIR spectrum

Comparison of the UV-Vis-NIR spectra of HT+P sapphires showed no differences between them and sapphires subjected to traditional heat treatment, or untreated sapphires. This is not surprising as the chromophore of each (intervalence charge transfer of Fe2+–Ti4+) is the same.

Infrared (IR) spectrum

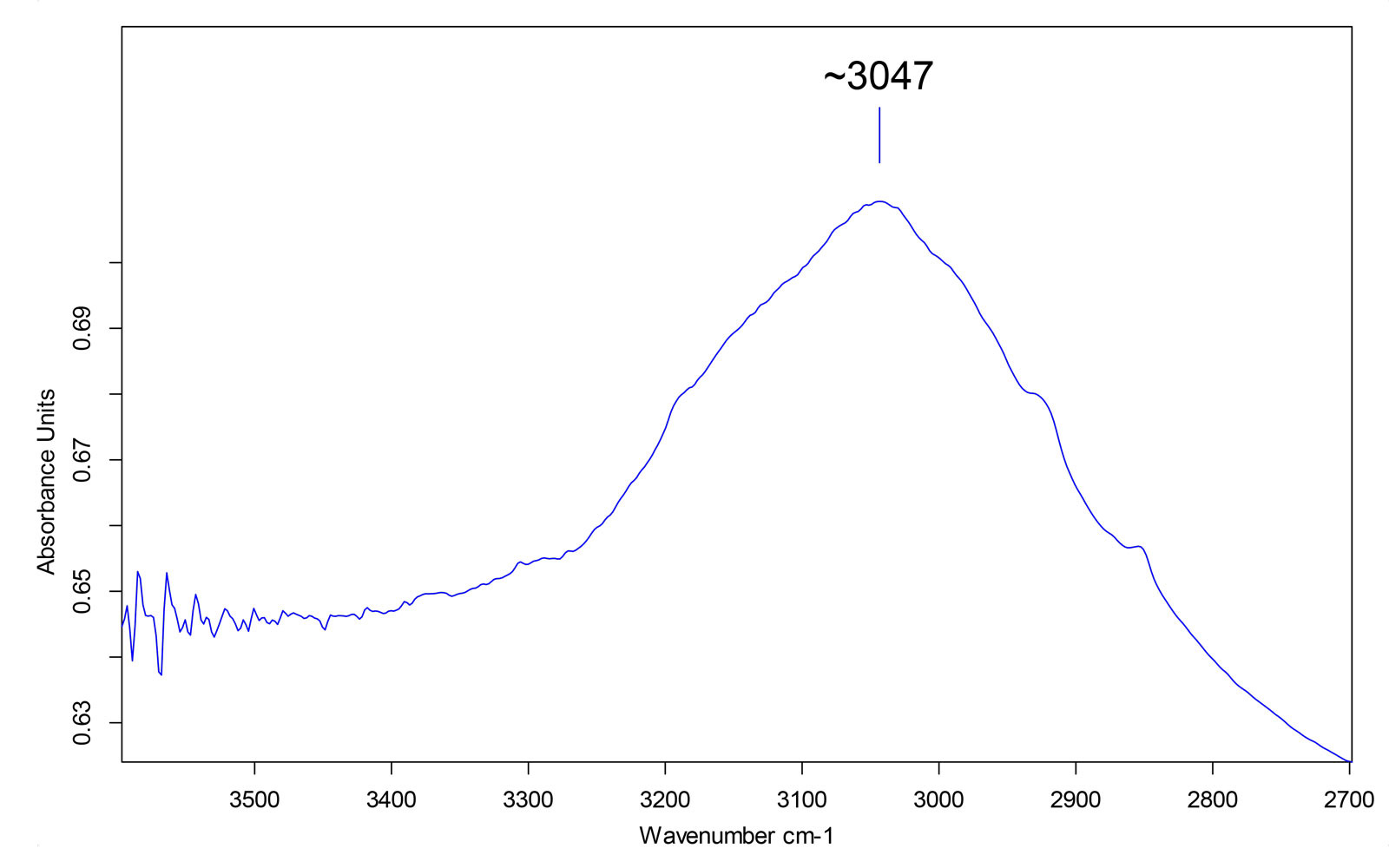

The one area where it is possible to separate HT+P sapphires from those heated by traditional methods is with the infrared spectrum. A significant percentage of HT+P stones display a broad peak at ~3047 cm–1.

The distinctive IR spectrum of some HT+P treated sapphires, with a broad peak at ~3047 cm–1. Unfortunately, this peak may be missing or obscured in many HT+P treated stones, or they may show spectra that are identical to those of conventionally heated sapphires. Spectrum: Lotus Gemology.The distinctive IR spectrum of some HT+P treated sapphires, with a broad peak at ~3047 cm–1. Unfortunately, this peak may be missing or obscured in many HT+P treated stones, or they may show spectra that are identical to those of conventionally heated sapphires. Spectrum: Lotus Gemology.

The distinctive IR spectrum of some HT+P treated sapphires, with a broad peak at ~3047 cm–1. Unfortunately, this peak may be missing or obscured in many HT+P treated stones, or they may show spectra that are identical to those of conventionally heated sapphires. Spectrum: Lotus Gemology.The distinctive IR spectrum of some HT+P treated sapphires, with a broad peak at ~3047 cm–1. Unfortunately, this peak may be missing or obscured in many HT+P treated stones, or they may show spectra that are identical to those of conventionally heated sapphires. Spectrum: Lotus Gemology.

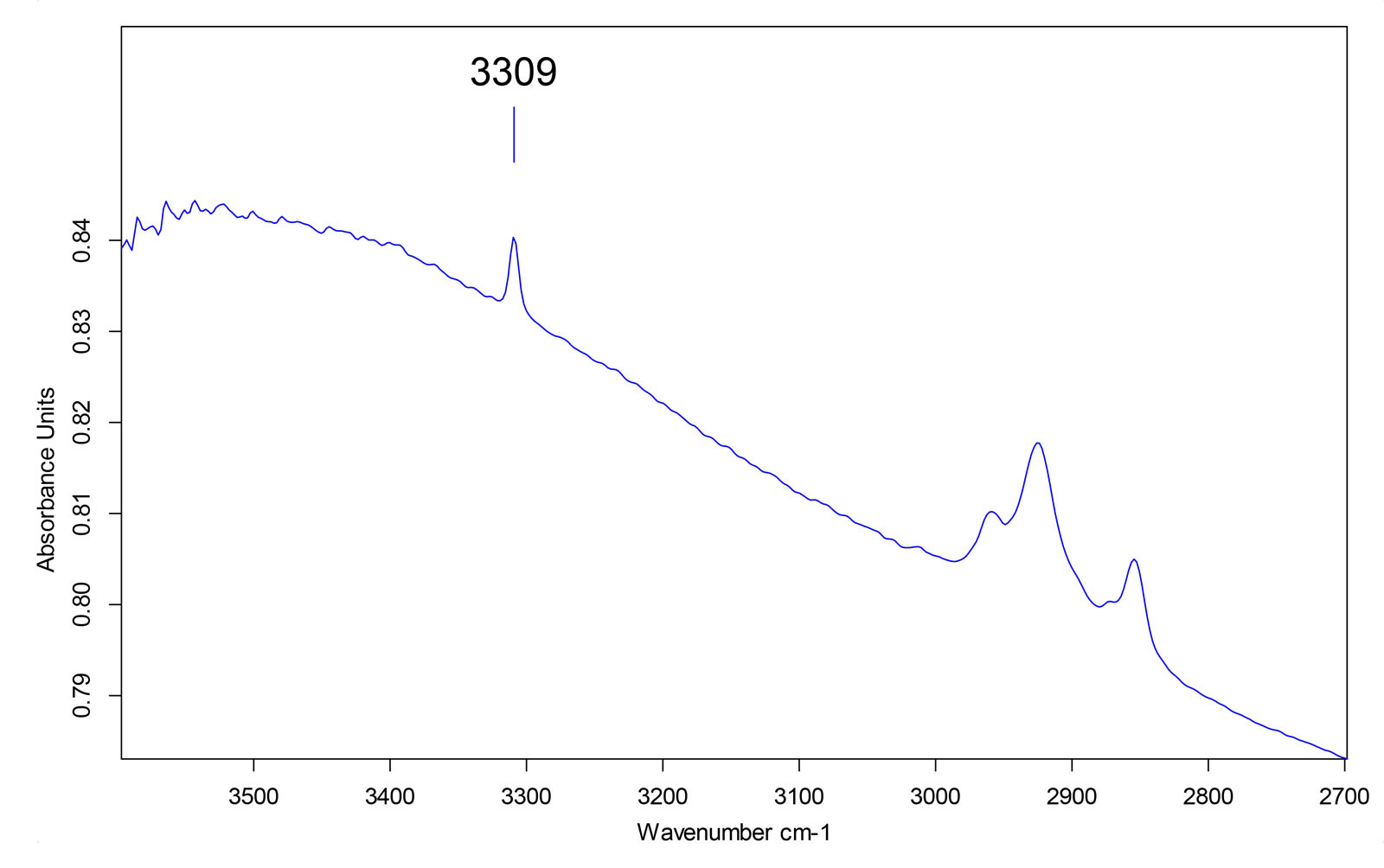

Natural untreated sapphire (and ruby) typically shows a peak at 3309 cm–1. It can be of varying intensities. Other IR spectra are also possible, but this is the most common type.

A single peak at 3309 cm–1 is characteristic of untreated blue sapphire. Spectrum: Lotus Gemology.

A single peak at 3309 cm–1 is characteristic of untreated blue sapphire. Spectrum: Lotus Gemology.

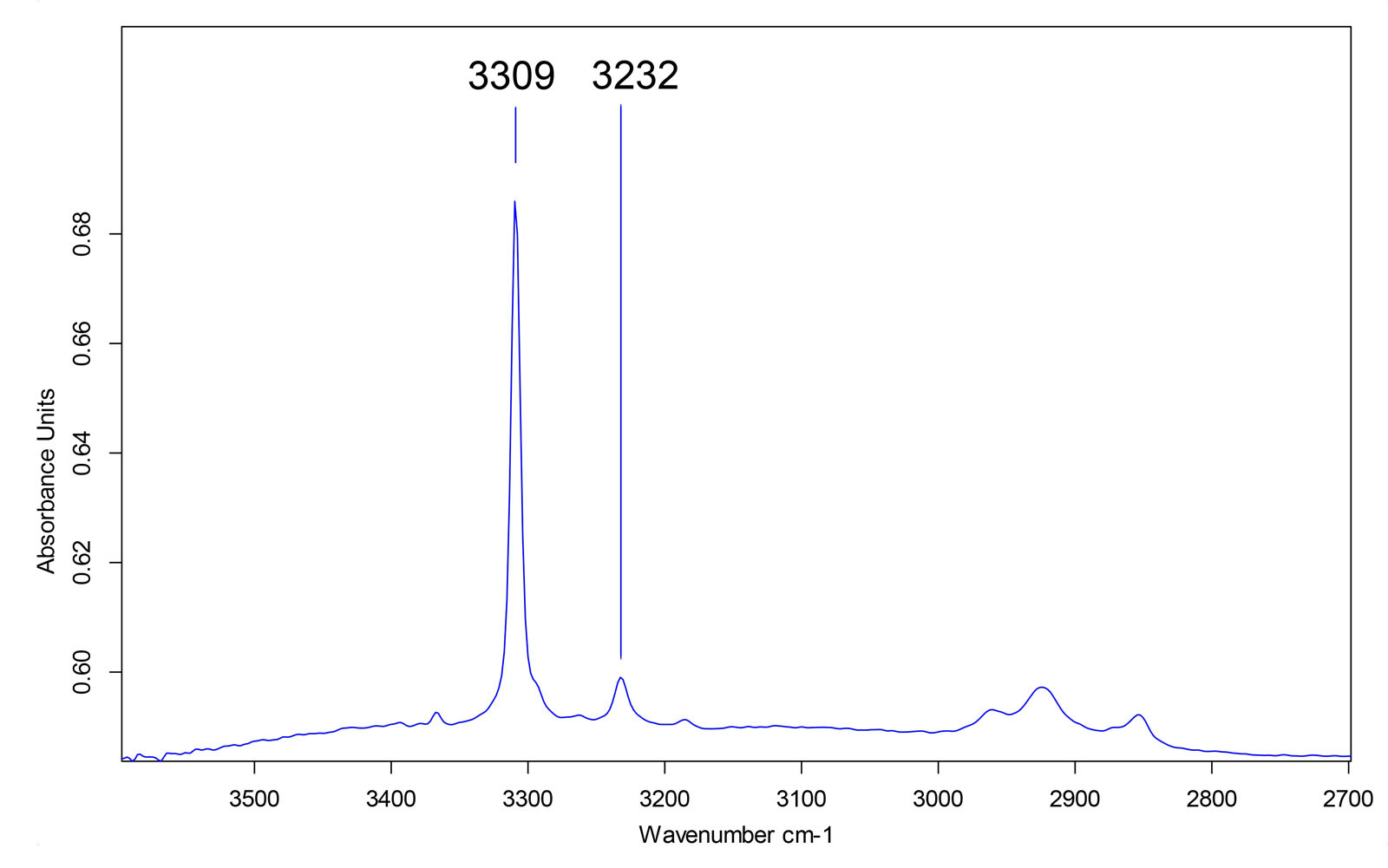

When low-Fe metamorphic sapphire is heat treated, it often develops a small peak at 3232 cm–1, in addition to the 3309 cm–1. The presence of this additional 3232 cm–1 peak is strong evidence of heat treatment in sapphire (and even in ruby). HT+P treated sapphires may also display this spectrum, as well as others. Spectrum: Lotus Gemology.

When low-Fe metamorphic sapphire is heat treated, it often develops a small peak at 3232 cm–1, in addition to the 3309 cm–1. The presence of this additional 3232 cm–1 peak is strong evidence of heat treatment in sapphire (and even in ruby). HT+P treated sapphires may also display this spectrum, as well as others. Spectrum: Lotus Gemology.

It is beyond the scope of this article to detail all the variations in IR spectra of corundum, treated and natural. There are dozens of possibilities. What is important to note is that the broad peak at about 3047 cm–1 suggests the stone is HT+P treated. However, the absence of that peak still leaves open a significant chance that the stone is HT+P treated.

Identification summary

The identification of HT+P treated sapphire can be summarized as follows, compared to traditionally heated sapphire:

- The microscope provides no clear-cut means of separation. At best, extremely subtle differences are seen in some fissures.

- Ultraviolet fluorescence, UV-Vis-NIR absorption, and trace element composition are not diagnostic for the treatment.

- While FTIR spectra can be diagnostic (~3047 peak in some HT+P treated sapphires), the spectra are quite variable and the ~3047 peak can even be removed with further heating. Many HT+P sapphires show IR spectra that are not diagnostic for the treatment.

Durability studies

The previously mentioned GRS study (Peretti et al., 2018, 2019) had reported two possible issues with durability on sapphires treated with high temperatures and pressure.

GRS reported:

"When we tried to scratch a facet edge of a HPHT-treated sapphire with a paper clip, the facet edges crumbled. A clear indication of reduced durability. When re-polishing the surfaces of HPHT-treated sapphires, the cutter reported that the stones got unusually hot. Further, when sawing the sapphires to produce wafers, we noticed certain samples were breaking off the last quarter of the sawing path.

"It is possible that only multi-step HPHT-treated sapphires (conventional heating plus additional HPHT-treatment) show this type of brittleness. However, it is safer to assume a higher degree of brittleness for all stones, once this new treatment method is detected."

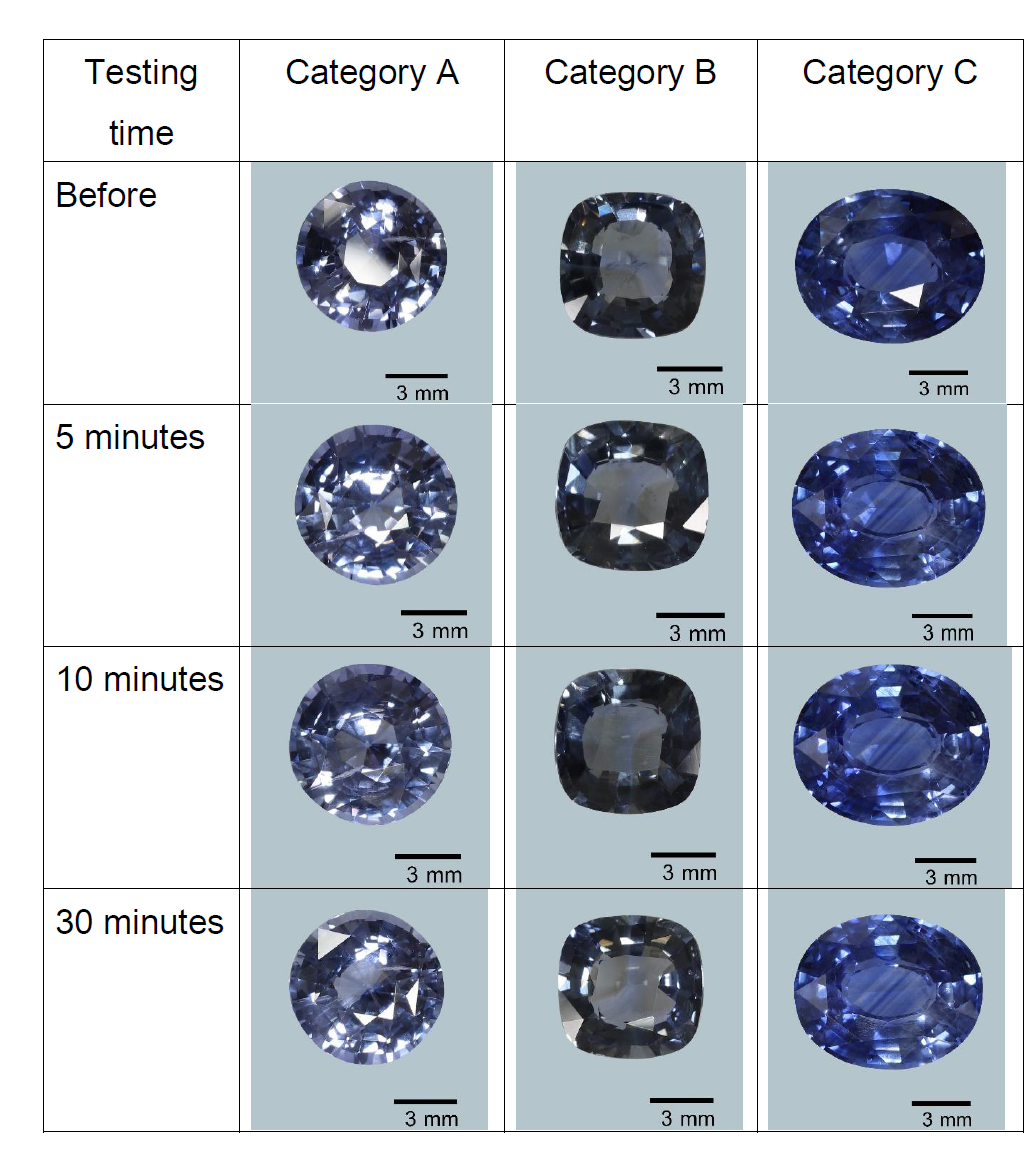

Obviously if true, this is a serious problem, and so particular attention was paid to durability testing of the treated stones. For this study, samples were chosen from three categories:

A. Eye clean

B. Included

C. Heavily included

In addition, one sample was faceted after treatment.

Ultrasonic cleaning

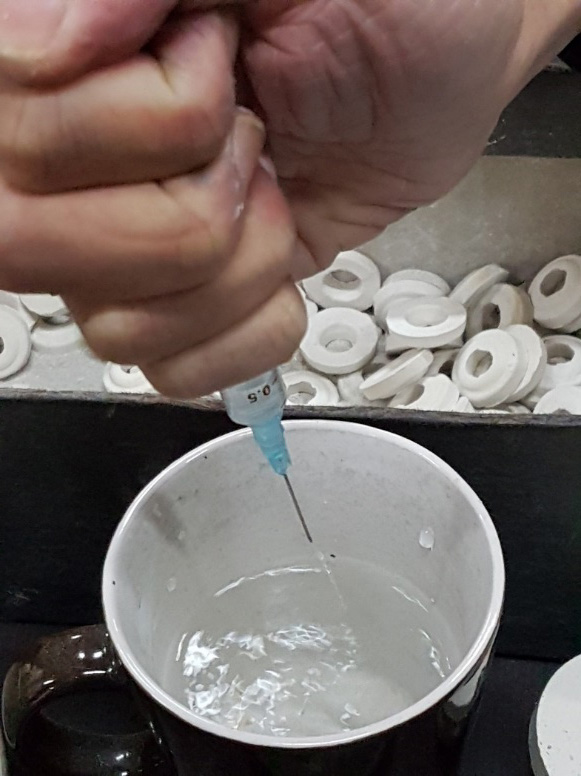

An ultrasonic bath was filled with slightly warm water. All samples were placed on a wire bucket and soaked for 5, 10, and 30 minutes respectively. The test at GIT revealed no damage on any of the stones.

A similar setup was chosen at GGL for four sapphires revealing by microscopic inspection no additional damage after the ultrasonic bath (beyond the pre-existing abrasions).

Following ultrasonic cleaning, none of the sapphires treated with high temperatures and modest pressure were found to show any damage whatsoever. Photo: GIT. Click on the photo for a larger image.

Following ultrasonic cleaning, none of the sapphires treated with high temperatures and modest pressure were found to show any damage whatsoever. Photo: GIT. Click on the photo for a larger image.

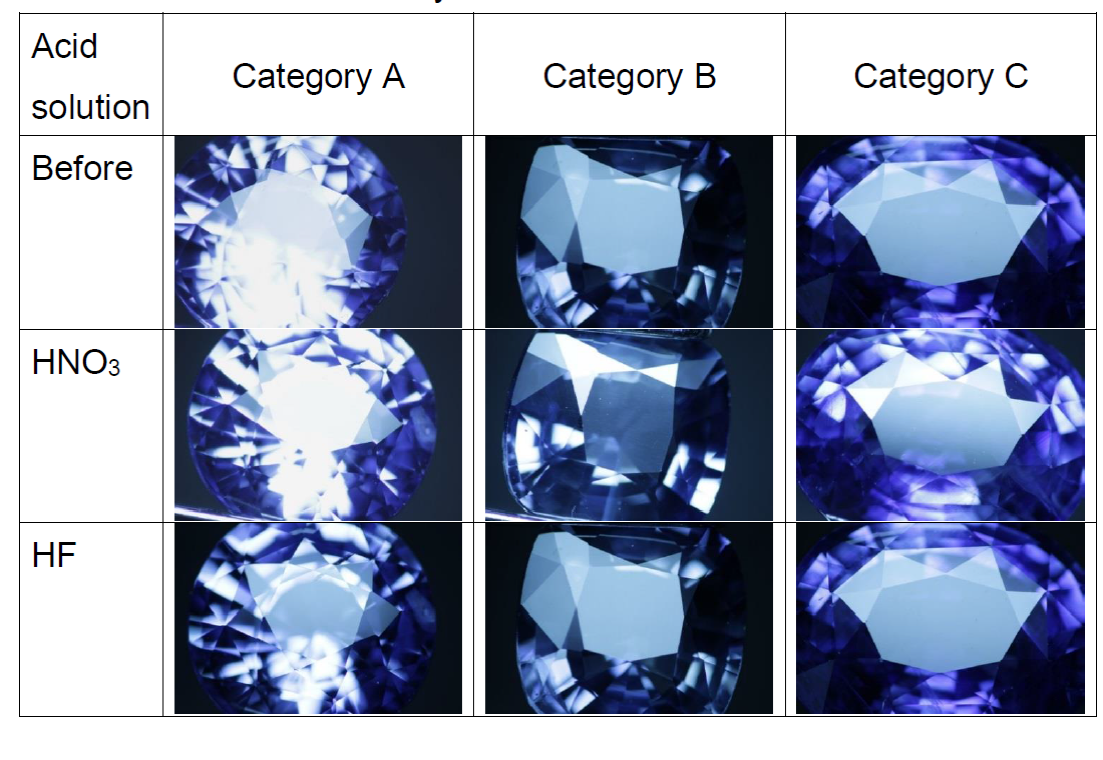

Acid resistance

Three sapphire samples (one of each category) were selected for:

A. Soaking in strong nitric acid (HNO3) for six hours and…

B. Soaking in strong hydrofluoric acid (70% HF) for two minutes.

No etching or other damage occurred.

Following acid immersion, none of the sapphires treated with high temperatures and modest pressure were found to show any damage whatsoever. Photo: GIT. Click on the photo for a larger image.

Following acid immersion, none of the sapphires treated with high temperatures and modest pressure were found to show any damage whatsoever. Photo: GIT. Click on the photo for a larger image.

Brittleness testing with paper clip and steel blade

Three stones (one of each category) were selected to be scratched by a paper clip (A) and cutter blade (B). We observed no damage to the stones, only flakes of metal that came off the paper clip and accumulated on the surface.

Attempting to scratch sapphires treated with high temperatures and pressure with a paper clip (top left) and a steel blade (top right) resulted in no damage whatsoever, only leaving debris from the metal on the stone's surface (below right). Photos: GIT. Click on the photos for larger images.

Attempting to scratch sapphires treated with high temperatures and pressure with a paper clip (top left) and a steel blade (top right) resulted in no damage whatsoever, only leaving debris from the metal on the stone's surface (below right). Photos: GIT. Click on the photos for larger images.

It should be noted that the specimen that GRS reported that they scratched with a paper clip was a stone that had been HT+P treated, but which had probably not been repolished following the treatment. Thus it is likely that they were simply scratching the graphite crust, not the sapphire itself.

|

|

Left: HT+P treated sapphire just after removal from the crucible. Note the soft graphite crust on the surface.

Right: The same sapphire after final polishing. Obviously, a paper clip could scratch the graphite crust, but it would have no impact on the sapphire after polishing. Photos: Imam Gems.

Drop testing

Three stones (one of each category) were selected and dropped onto a hard concrete floor from approximately one meter height. This procedure was repeated three times for each stone. No damage (cracking) was observed in any of the samples.

Resistance to thermal shock

Three stones (one of each category) were selected and heated with a jeweler's torch for five seconds until each of them started to glow red. No change of color occurred due to the testing. One stone from category C (which was already highly included) developed additional tension cracks extending from internal inclusions. This is to be expected from any highly included sapphire, treated or not.

Following heating with a jeweler's torch, only one stone in Category C (highly included) showed damage. This is to be expected from any highly inluded sapphire, treated or not. Photos: GIT. Click on the photos for larger images.

Following heating with a jeweler's torch, only one stone in Category C (highly included) showed damage. This is to be expected from any highly inluded sapphire, treated or not. Photos: GIT. Click on the photos for larger images.

Repolishing

A Montana sapphire from the GIA reference collection was heated with pressure in South Korea and subsequently faceted. No damage occurred during polishing and cutting.

|

|

|

| Before treatment: 4.68 ct | After treatment: 4.68 ct | After treatment and cutting: 1.86 ct |

Hammer test

In the GRS report, they showed a photo of a sapphire that had been subjected to a "hammer test" and had broken into three pieces. Quoting from their report:

[This photo shows] three fragments of a stress tested cabochon impacted by hammer created triangular fragments with newly formed cracks radiating toward the center of the stone.

To test this claim, SSEF subjected a basalt-related sapphire that had undergone conventional heat treatment to a hammer test. The results are shown in the photo below:

A basalt-related sapphire (left) that was heat treated by conventional methods was subjected to a hammer test, which caused it to break into many fragments (right). Photo: SSEF

A basalt-related sapphire (left) that was heat treated by conventional methods was subjected to a hammer test, which caused it to break into many fragments (right). Photo: SSEF

Summary of durability issues

The claims of brittleness/durability problems of HT+P treated sapphires could not be substantiated by our tests, which were carried out by several laboratories simultaneously. But they did reveal that subjecting heavily included starting material (low quality) to stress may produce fissures and cracks (durability issue), regardless of which heating method ('traditional' or 'new') is applied.

We should remember that all corundums, not just stones subjected to heat treatment, have a degree of brittleness. As the famous British gemologist Robert Webster wrote in his 1962 magnum opus Gems:

"Despite their hardness, ruby and sapphire need to be handled with some care, for they are to a slight extent brittle and if dropped on a hard surface or given a sharp blow tend to develop internal flaws and cracks."

Robert Webster, Gems 1962

Untreated Ceylon sapphire showing wear marks with extensive facet abrasions and chips. This amply demonstrates that sapphire is somewhat brittle by nature, whether treated or not. Photo: Richard Hughes/Lotus Gemology. Click on the photo for a larger image.

Untreated Ceylon sapphire showing wear marks with extensive facet abrasions and chips. This amply demonstrates that sapphire is somewhat brittle by nature, whether treated or not. Photo: Richard Hughes/Lotus Gemology. Click on the photo for a larger image.

Questions regarding HT+P treated sapphires

Q. Are there durability problems that result from this treatment?

A. Our studies revealed none.

Q. Does treatment produce significant advantages in terms of improvements in clarity (fissure healing, etc.)?

A. The differences we have seen are generally slight and not unlike sapphires conventionally heated at high temperatures.

Q. Does this treatment significantly increase the supply of sapphire in the market?

A. To date, it has not.

Q. What percentage of stones that have been subjected to this treatment are currently identifiable by labs?

A. We simply do not know because many HT+P treated sapphires cannot be separated from conventionallyheated stones.

Q. Does this treatment warrant separate disclosure beyond just heat?

A. Based on our current information, we believe it does not. But this could change if further information comes to light.

Summary

In their Industry Advisory (AGTA, 2018), the AGTA stated the following:

This new treatment does improve the apparent quality of the sapphire and as such is subject to both Federal Trade Commission Guides for the jewelry industry and the AGTA's Code of Ethics about treatment disclosure. For that reason, this new treatment must be disclosed, in writing, by the seller to the buyer as pressure and heat treatment with the following AGTA Disclosure Code: HP

We have clearly documented the fact that the trade only creates new categories of treatments when there are specific significant differences in a new treatment. This would apply to:

- Outside-in diffusion of chromophores (Be, Cr & Ti diffusion)

- Significant healing of fissures (flux healing of Mong Hsu ruby, etc.)

With HT+P treated sapphires, we do not find either of these things. In addition, the durability problems cited by GRS could not be duplicated in our tests. We have found no evidence that this treatment does anything that could not be done with heat alone. As a result, we believe this treatment should not require specific disclosure beyond declaring the stones as heated.

References

- AGTA (n.d.) AGTA Gemstone Information Manual. American Gem Trade Association, 15th edition.

- AGTA (2018) AGTA Industry Gemstone Advisory [concerning sapphire heated with high temperatures and low pressures]. American Gem Trade Association, 8 December 2018.

- Anonymous (1916) Sapphire-mining industry of Anakie, Queensland. Bulletin of the Imperial Institute, Vol. 14, April–June, pp. 253–261.

- Beruni, M.i.A., al- (1989) The Book Most Comprehensive in Knowledge on Precious Stones: al-Beruni’s Book on Mineralogy [Kitab al-jamahir fi marifat al-jawahir]. Trans. by Said, H.M., One Hundred Great Books of Islamic Civilization, Natural Sciences No. 66, Islamabad, Pakistan Hijra Council, 355 pp.

- Choi H.M., Kim S.K. and Kim Y.C. (2014a) Appearance of new treatment method on sapphire using HPHT apparatus. ICGL Newsletter, No. 4, pp. 1–2.

- Choi H.-M., Kim S.-K. and Kim Y.C. (2014b) New treated blue sapphire by HPHT apparatus. Proceedings of the 4th International Gem and Jewelry Conference (GIT2014), Chiang Mai, Thailand, 8–9 December, pp. 104–105.

- Choi H., Kim S., Kim Y., Leelawatanasuk T., Lhuaumporn T., Atsawatanapirom N., Ounorn P. (2018) Sri Lankan sapphire enhanced by heat with pressure. Journal of The Gemmological Association of Hong Kong, Vol. 39, pp. 16–25.

- Crowningshield, R. (1966) Developments and Highlights at the Gem Trade Lab in New York: Unusual items encountered [sapphire with unusual fluorescence]. Gems & Gemology, Vol. 12, No. 3, Fall, p. 73.

- Hughes, R.W. and Galibert, O. (1998) Foreign affairs: Fracture healing/filling of Möng Hsu ruby. Australian Gemmologist, Vol. 20, No. 2, April–June, pp. 70–74.

- Emmett, J.L., Scarratt, K. et al. (2003) Beryllium diffusion of ruby and sapphire. Gems & Gemology, Vol. 39, No. 2, Summer, pp. 84–135.

- Hughes, R.W. and Emmett, J.L. (2004) Fluxed up: The fracture healing of ruby. The Guide, Vol. 23, Issue 5, Part 1, Sept.–Oct., pp. 1, 4–9.

- Hughes, R.W., Manorotkul, W. & Hughes, E.B. (2014) Ruby & Sapphire: A Collector's Guide. GIT, Bangkok, 384 pp.

- Hughes, R.W., Manorotkul, W. & Hughes, E.B. (2017) Ruby & Sapphire: A Gemologist's Guide. Lotus Publishing, Bangkok, 816 pp.

- Keller, P.C. (1982) The Chanthaburi-Trat gem field, Thailand. Gems & Gemology, Vol. 18, No. 4, Winter, pp. 186–196.

- Kim, S.-K., Choi, H.-M., Kim, Y.-C., Wathanakul, P., Leelawatanasuk, T., Atsawatanapirom, N., Ounorn, P. and Lhuaamporn, T. (2016) Gem Notes: HPHT-treated blue sapphire: An update. Journal of Gemmology, Vol. 35, No. 3, July, pp. 208–210.

- Nassau, K. (1981) Heat treating ruby and sapphire: Technical aspects. Gems & Gemology, Vol. 17, No. 3, Fall, pp. 121–131.

- Peretti, A., Musa, M., Bieri, W., Cleveland, E., Ahamed, I., Mattias, A., & Hahn, L. (2018, 2019) Identification and characteristics of PHT (‘HPHT’)-treated sapphires: An update of the GRS research progress. GemResearch SwissLab, online report, first posted 12 November 2018; updated 15 January 2019; first accessed 12 November 2018.

- Song, J. Noh, Y., and Song, O., 2015. Color enhancement of natural sapphires by high pressure high-temperature process, Journal of the Korean Ceramic Society, Vol. 52, No. 2, pp. 165–170.

Note: For those who wish to explore the literature further, see Four Treasures: Lotus Gemology's Reference Database.